ROMAG-PROD Heavy Water Plant produces:

Heavy

Water

All the activities related to heavy water production process: designing,

manufacturing, operation have been elaborated under a Quality Assurance

regime intended to provide a safe and reliable plant operation. The

manufacturing process control is automated, being provided with alarming

and quick emergency answer systems that are activated in case working

parameters exceed the allowed limits. Heavy water is obtained from Danube

River waters, which, as all surface continental waters, naturally contain

a heavy water quantity of 0.0145%. This heavy water existing in natural

water, is separated and enriched within ROMAG-PROD Plant up to a nuclear

grade concentration of minimum 99.78%. The process of heavy water producing

is based on isotopic exchange between water and hydrogen sulphide in

bi-therm system, inside of Girdler-Sulphide plants, where a primary

enrichment in Deuterium is reached up to approx 4-12%, based on the

following reaction:

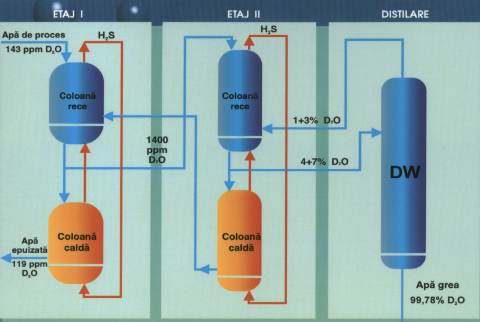

The filtered and treated Danube water reacts with hydrogen sulphide within a production line with 2 stages of bi-therms (stage I and stage II), at two different temperatures, with an enrichment in first stage from 0.0143% to 0.14% followed by a final concentration within a distillation under vacuum installation where nuclear grade concentration of heavy water is reached.

Girdler-Sulphide isotopic exchange installation:

Technical specifications:

| Quality Parameter | Value | Measurement Unit |

| Isotopic concentration | min. 99.78* | % wt. D2O |

| Conductivity | max. 5 | micro S/cm |

| Turbidity | max. 1 | NTU (ppmSiO2) |

| Organics (KmnO4 demand) | max. 10 | mg/Kg |

| Chlorides | max. 0.5 | mg/Kg |

| Tritium | absent | micro Ci/kg |

Deuterium Depleted Water - DDW

Within heavy water manufacturing plants from ROMAG-PROD, a highly advanced isotopic separation is performed and, finally, a kind of water with a very low Deuterium concentration level is also obtained. Deuterium Depleted Water process is realized by vacuum distillation of natural water or effluent water coming from heavy water plant processing, continuously, with an constant extraction flow and, depending on supplying points placed on different height levels of distillation tower, the desired grade of Deuterium depletion of the water is reached.

Technical specifications:

| Quality Parameter | Value | Measurement Unit |

| Isotopic concentration | max. 80* | D2O ppm |

| Conductivity | max. 5 | micro S/cm |

| Turbidity | max. 1 | NTU (ppmSiO2) |

| Organics (KmnO4 demand) | max. 10 | mg/Kg |

| Chlorides | max. 0.5 | ppm |

| Biologic Purity | absent | No germs |

* Depending on Deuterium concentration, ROMAG-PROD Deuterium Depleted Water is classified as:

| Code | D2O ppm |

| SU1 | 0 - 20 |

| SU2 | 21 - 40 |

| SU3 | 41 - 60 |

| SU4 | 61 - 80 |

High-Grade Heavy Water

ROMAG-PROD Heavy Water Plant also produces high grade heavy water of a concentration greater than 99.96%.

Technical specifications:

| Quality Parameter | Value | Measurement Unit |

| Isotopic concentration | min. 99.90* | % wt. D2O |

| Conductivity | max. 5 | microS/cm |

| Turbidity | max. 1 | NTU(ppmSiO2) |

| Organics (KmnO4 demand) | max. 10 | mg/Kg |

| Chlorides | max. 0.04 | ppm |

| Tritium | absent | microCi/kg |

*Depending on Deuterium concentration, ROMAG-PROD High Grade Heavy Water is classified as:

| Code | %wt. D2O |

| HG | 99.90 |

| VHG | 99.96 |

| EHG | 99.9996 |